2026 Best Commercial Bakery Equipment for Professional Bakers?

In the competitive world of baking, choosing the right commercial bakery equipment is crucial for success. Chef Mario Ruiz, a leading expert in the industry, states, "Investing in quality equipment can transform your baking process and boost your output." This sentiment echoes a challenge many bakers face: balancing quality, efficiency, and cost.

As professional bakers explore the best options in 2026, they must consider various equipment types. Ovens, mixers, and proofers each have unique features that affect the final product. Proper selection can mean the difference between a delightful pastry and a wasted batch. Yet, many bakers may overlook the benefits of state-of-the-art technology. This often leads to missed opportunities for innovation.

Maintaining equipment is another significant challenge. Routine upkeep can feel overwhelming, and neglect can lead to costly downtime. While high-quality equipment may offer reliability, the best choices require constant learning and adaptation. Finding the perfect commercial bakery equipment is not just about the initial investment; it’s also about long-term growth and sustainability.

Overview of Commercial Bakery Equipment Types for 2026

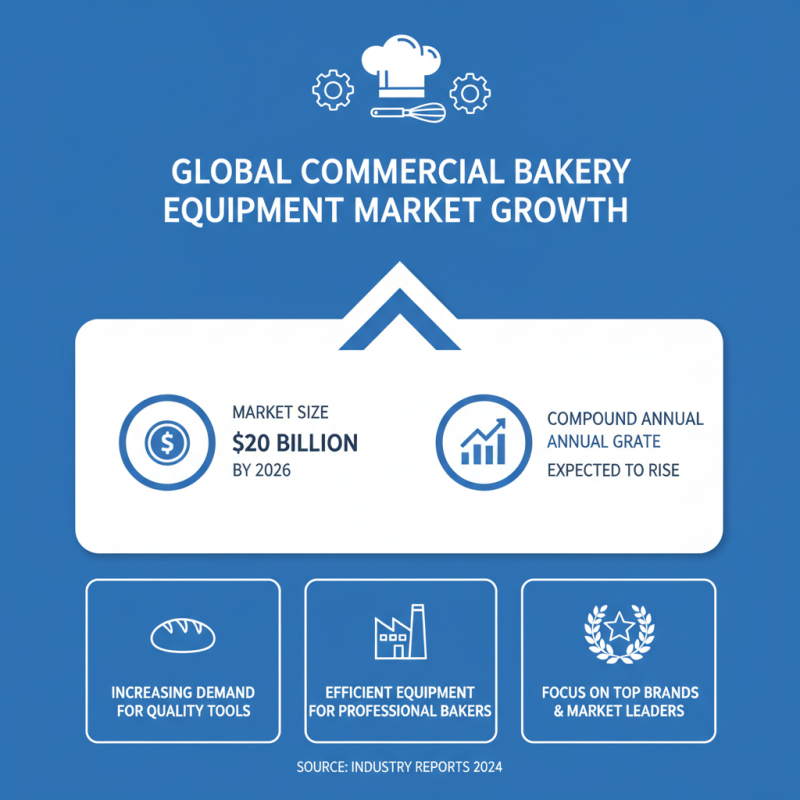

When exploring commercial bakery equipment types for 2026, focusing on essentials is key. Equipment can significantly impact efficiency and product quality. Professional bakers should consider mixers, ovens, proofers, and refrigeration units as fundamental tools. According to industry reports, the global bakery equipment market is expected to grow at a CAGR of 4.6% from 2021 to 2026. This growth reflects a rising demand for innovative and efficient baking solutions.

Mixers are vital for achieving perfect dough consistency. While spiral mixers are popular, planetary mixers offer versatility for different tasks. Remember, choosing the right size can prevent overworking the dough and impacting texture.

Ovens vary widely, from traditional deck ovens to high-tech combi ovens. Each type has unique benefits that can elevate baking outcomes. Bakers should also assess energy efficiency, as this can influence long-term costs and sustainability.

Tip: Regular maintenance can prolong equipment life and enhance performance. For proofers, proper humidity levels are crucial. This affects yeast activity and overall dough rise. Every baker should monitor their equipment closely to avoid costly breakdowns. Balancing quality and budget is essential. Investing in the right tools can elevate your baking game. However, commitment to continuous learning is equally important. Always keep an eye on industry trends and technology advancements.

Key Features to Consider in Professional Bakery Equipment

When selecting commercial bakery equipment, certain features are essential for professional bakers. Durability is key. Equipment that withstands heavy use is critical in a busy kitchen. Look for stainless steel materials. These not only resist corrosion but also simplify cleaning.

Precision temperature control greatly affects baking. Ovens that maintain consistent heat help achieve perfect results. Consider models with digital displays for easy monitoring. A reliable mixer should also mix evenly, reducing manual effort. Look for features like multiple speed settings, which offer flexibility for various recipes.

Tip: Always read reviews from fellow bakers. Their experiences can provide insights about reliability and performance. It’s tricky to find the right equipment that meets all needs. Another consideration is space. Though larger ovens seem appealing, sometimes a compact option fits better. Evaluate the layout of your kitchen and choose wisely.

Top Brands and Market Leaders in Commercial Bakery Equipment

When exploring commercial bakery equipment, it's vital to consider top brands and market leaders. The global commercial bakery equipment market is expected to grow significantly, reaching approximately $20 billion by 2026. This growth highlights the increasing demand for quality and efficient tools among professional bakers.

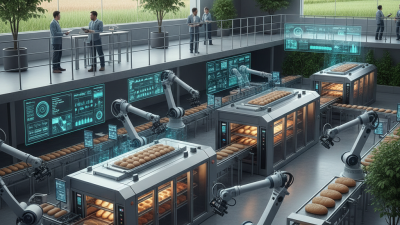

Professional bakers rely heavily on innovative equipment to improve efficiency and ensure product consistency. The demand for automated solutions is on the rise, driven by the need to enhance production speed. Industry reports indicate that energy-efficient machines are becoming essential. They reduce operating costs and minimize environmental impact. Yet, many bakeries still use outdated equipment that hinders their potential. Transitioning to modern equipment can be a daunting process, requiring significant investment and training.

Despite advancements, the learning curve remains an obstacle. Not every bakery adopts new technologies seamlessly. Some bakers struggle to integrate sophisticated machinery into their workflows. This can lead to frustration and inefficiencies. However, as the market evolves, those who embrace change tend to stay ahead. Understanding the current trends assists bakeries in making informed decisions. Balancing quality and cost is crucial for achieving success in this competitive landscape.

Latest Innovations in Baking Technology for 2026

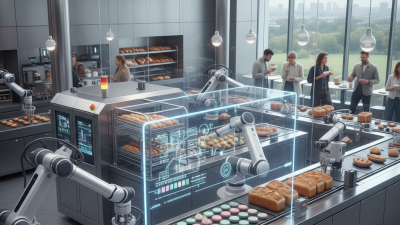

The world of baking technology is evolving rapidly. In 2026, new innovations are set to enhance efficiency and creativity for professional bakers. Advances in automated mixers and programmable ovens allow for precision and consistency. These machines can streamline the baking process, reducing labor time significantly.

Tips: Explore machines that offer customizable settings. This can help you achieve your unique recipes more reliably. Also, consider investing in energy-efficient equipment. It saves money and promotes sustainable practices.

Another exciting trend is the use of smart technology in baking. Equipment that connects to apps can monitor temperatures and timings. This makes it easier to manage multiple tasks at once. However, relying too much on technology might lead to forgetting traditional techniques. Striking a balance is essential for creativity.

Tips: Always test your methods manually, even with smart equipment. Familiarity with old-school techniques can inspire new creations. Lastly, keep learning about these innovations. Technology is changing baking in unexpected ways. Embrace the change, but don't forget the basics.

Cost Analysis: Budgeting for Quality Bakery Equipment Investments

Investing in bakery equipment is crucial for professional bakers. Upfront costs can be staggering. Quality mixers, ovens, and proofers are essential, but they come with a price tag. On average, a good oven may range from several thousand to tens of thousands. High-quality equipment lasts longer, offering better returns over time. It’s vital to balance cost with potential output.

Budgeting isn't just about upfront costs. Maintenance and repairs are often overlooked. A broken mixer can halt production. Planning for these expenses is essential. Not accounting for them could strain a budget. Set aside a portion of profits for upkeep. When equipment fails, this fund can provide a safety net.

Consider the hidden costs, too. Installation, training staff, and energy usage may also affect your budget. Many bakers underestimate these factors. Evaluating total expenses ensures a realistic financial plan. Without careful consideration, bakeries may struggle to thrive. Take the time to research thoroughly.

2026 Best Commercial Bakery Equipment Cost Analysis

Related Posts

-

2025 Top 10 Must Have Baking Equipment for Every Home Baker

-

2025 Top 10 Bakery Systems You Need to Know for Your Business

-

How to Optimize Bakery Industrial Processes for Maximum Efficiency

-

Top 10 Bakery Systems Tips to Improve Your Business Efficiency

-

2025 How to Bake Bread: Tips for Perfect Homemade Loaves Every Time

-

Top 10 Essential Bread Making Equipment for Perfect Homemade Bread